As the world becomes increasingly connected, the demand for digital devices is rising and data centers operate around the clock. Exyte is constantly working on technical solutions to overcome the environmental challenges that come with such demand. Energy-efficient data centers and semiconductor fabrication plants (fabs) play a critical role in this, as does Exyte’s ExyCell® for the biopharma and life sciences industry. Exyte experts Taib Shabbir, Manfred Engelhard, and Luca Mussati are working closely to incorporate sustainability into these industries.

.jpg?w=3840)

The journey to sustainability begins at the planning stage

"My main role is to decarbonize the semiconductor fabs we build for our clients," says Shabbir, who has been working in sustainability for about 15 years. Semiconductor manufacturing is inherently an energy-intensive operation. While chip makers are determined to reduce their carbon emissions, not every location has sufficient green energy available from the grid. Fossil fuels still dominate the energy sector in many parts of the world.

“At Exyte, we know that sustainability measures need to be considered early during the planning stage before a new fab is built to have a larger impact on carbon footprint reduction during the clients’ operations.” It is more complex and costly to implement such measures at an already fully operating facility. “To sum it up, the earlier we plan for it, the lower the cost and the higher the impact,” Shabbir adds.

Engineers like Shabbir analyze every carbon emission source and its quantity within the fab. They look at the embodied carbon of building materials and at the emissions produced during construction and operation. “We also only use as much concrete as necessary since this is a highly carbon intensive building material,” Shabbir explains. “Wherever feasible we prefer to use steel which has a higher recycled content and is easier to recycle instead of concrete.”

Solutions for water and power consumption

Once a semiconductor factory is built, it needs plenty of electricity and water for production and operation. The wafers, silicon discs on which the semiconductors are created, undergo hundreds of processes and cleaning with various gases, chemicals, and ultra-pure water. The wastewater, in turn, must be treated before it can be looped back into the water cycle.

“Exyte has the expertise to enable the fabs to recycle a high percentage of the wastewater,” Shabbir says. But wastewater recycling requires a lot of energy too and that brings conflicts which the stakeholders must resolve for the fab to be truly sustainable. “Digital modeling and dynamic simulation can help us find the balance between the use of electricity and water,” explains Shabbir.

“Sustainability is the key to growth”

Exyte places particular emphasis on driving decarbonization through technological solutions. That is one of the reasons Shabbir enjoys being part of the Exyte team. "Working for a company which has sustainability as a key focus is important as I want to contribute to making a better world for the next generation. It is a goal that doesn't contradict the economic ambitions which both Exyte and our clients have. Sustainability is the key to growth,” he concludes.

Semiconductors also have an impact on the energy efficiency of other industries, such as data centers. Technological solutions based on high-quality semiconductors can limit the energy requirements and reduce cooling in data centers.

.jpg?w=3840)

Making data centers more sustainable

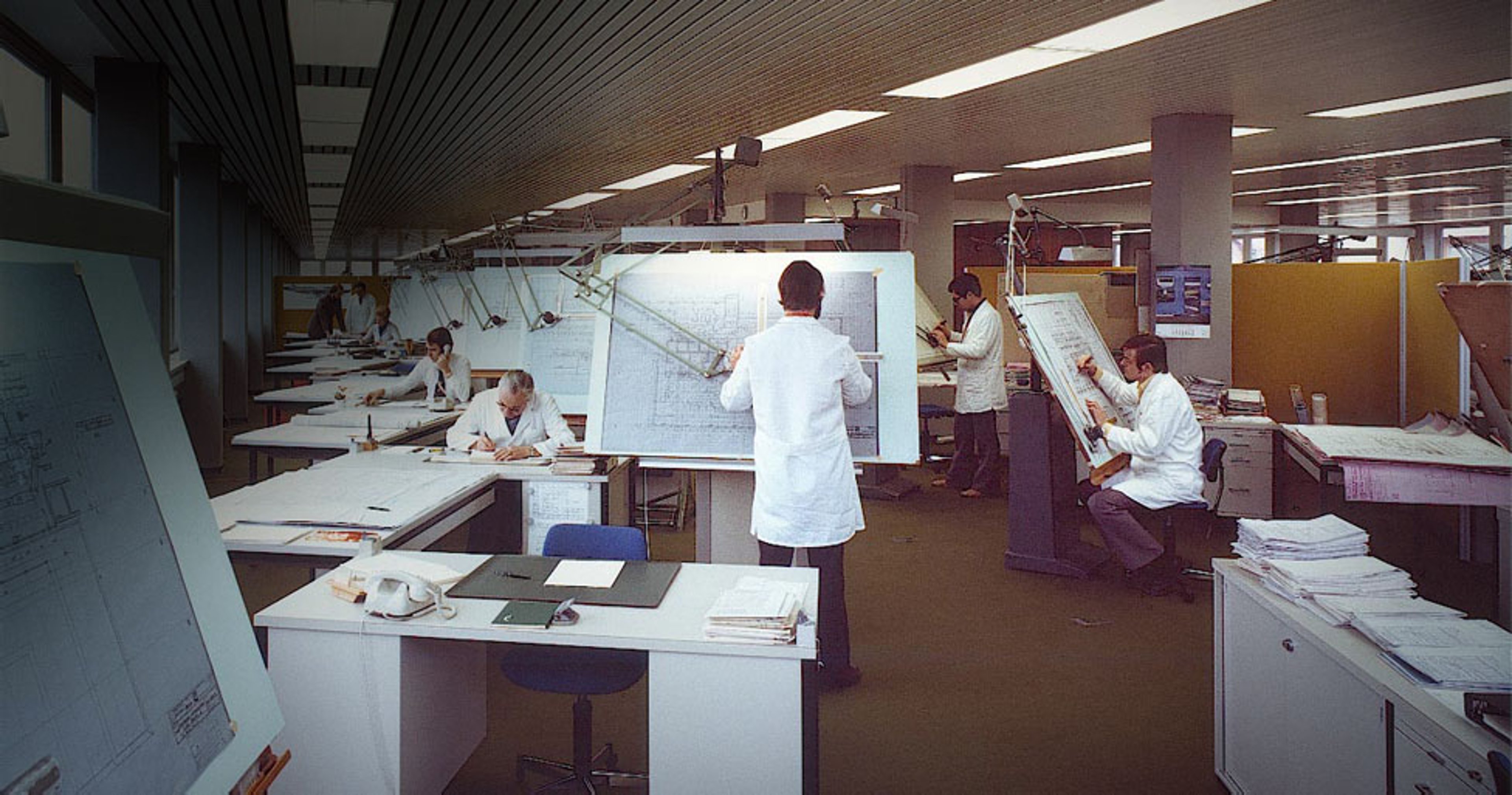

At Exyte's headquarters in Stuttgart, Manfred Engelhard is the subject matter expert on sustainable data center solutions. As the Director of Technology, he has more than 30 years of experience developing and delivering energy efficient solutions. Leaving a better environment for future generations is a matter close to his heart.

For Engelhard, as for Shabbir, sustainability begins with prudent planning of the building and its construction. Which building materials are particularly sustainable, have low embodied carbon or contain recycled content? Many building materials, such as steel support columns, can be reused.

In data center construction alternative building materials like low carbon concrete and timber are often a good alternative to concrete and steel because of the lower embodied carbon. Strategies like reducing floor heights and reducing the size of the overall building focus on an optimal use of resources. “Technological solutions that benefit the environment such as CO2-free fuels for the operation of generators are also being adopted in data centers,” says Engelhard.

"We need data centers for our modern way of life,” Engelhard states. “They are key not only for our everyday businesses but also essential for artificial intelligence applications, autonomous driving, life science and research."

As much horsepower as 630 Volkswagen Golfs

Data centers need lots of power. Exyte builds data centers for hyperscale cloud providers, which network millions of servers across the globe. Power required for the operation of just one data center can be more than 60 megawatts.

To break it down, 60 megawatts of power is the equivalent of more than 80,000 horsepower. It is as much as eight high-speed trains or approximately 630 Volkswagen Golfs. Those 60 megawatts not only power the many servers in the facility, but also the facility cooling and support systems. Without a cooling system the servers would quickly overheat leading to a system failure.

"We already have technologies for ‘direct to chip cooling’ that can be used to collect the heat directly at the chip level of the servers and deliver it to municipal utilities, for example, to heat entire residential neighborhoods," Engelhard explains.

He adds that this, however, also requires municipalities or local utility companies to provide the infrastructure to absorb the waste heat for district heating systems. "Each of our data centers allow for this technology to be used and there are municipalities that are interested in tapping into this resource," says Engelhard. European regulations about data center heat re-use and energy efficiency will accelerate the sustainability trend, such as the German “Energieeffizienzgesetz”, a new law for energy efficiency.

Data Centers not only as consumers of energy

Engelhard sees data centers in relation to their immediate environment: what can they give back to the environment where they operate? Whether it is heat recovery or in emergency situations such as power shortages, their huge emergency generators can support the power grid to prevent power outages. “Data centers would not only store your data, but also make sure the lights stay on," says Engelhard. Here, too, there have already been talks with power grid system operators about how they can benefit from data centers in powerplant emergency situations.

.jpg?w=3840)

Innovations that make facilities more sustainable

While data centers are an important and significant aspect of Exyte’s technologies, it’s not the only area within the company that is on a mission to create a better future for the planet. Designing sustainable biopharma and life sciences facilities is also motivating and challenging employees at Exyte.

This isn't an industry built on just producing lifesaving medicines that are both pure and flawless, it is also one that comes under strict production and design regulations. This is because biopharma and life sciences facilities are subject to the rules of Good Manufacturing Practices (GMP). These ensure factories are built to high standards without compromising production quality. This is the key challenge for engineers: design pharma facilities to improve sustainability without compromising GMP.

.jpg?w=3840)

ExyCell® reduces the need for resources

Exyte Vice President of Technology and Innovation for Biopharma and Life Sciences, Luca Mussati is passionate about sustainability and believes Exyte has a key role in the industry. "The company develops new sustainable solutions for a client, which it can also offer to other corporations after successful implementation,” he remarks. “This 'cross fertilization' makes Exyte an innovation driver in the industry."

One of Exyte's key innovations, the ExyCell® cleanroom modular system, is not only ahead of the competition when it comes to flexible prefabricated facilities but is also a sustainable solution. The ExyCell's® Plenum Integrated Filter Fan (PIFF) for heating, ventilation and air conditioning reduces energy consumption by up to 50 percent. It can be digitally controlled via the Internet of Things (IoT) and optimized through Digital Twins and Artificial Intelligence solutions to minimize energy consumption.

“We use our ingenuity and experience to design more energy-efficient facilities,” says Mussati. The trained engineer is not only interested in saving as much energy as possible professionally, but also personally. "I always travel by train whenever possible. And at the moment I'm renovating my home to make it more energy efficient. Solar roof, heat pump. It's important to me that we leave a better world for our children."

Excited to build a better future with us?

ARE YOU LOOKING FOR:

.jpeg?w=3840)

Newsroom

.jpeg?w=3840)

Fostering of sustainability

100+ Years of history

ARE YOU LOOKING FOR:

.jpeg?w=3840)

World of Exyte

/221211_PHO_BLS_Pharma_1.jpeg?w=3840)